Starting a ship’s main engine is not as easy as starting your car. It involves multiple steps and safety precautions to avoid any mishaps and ensure everything runs smoothly. Let’s discuss the steps involved in starting a ship’s main engine, from checking the fuel supply and lubrication system to engaging the turning gear and air starting system until navigational full status.

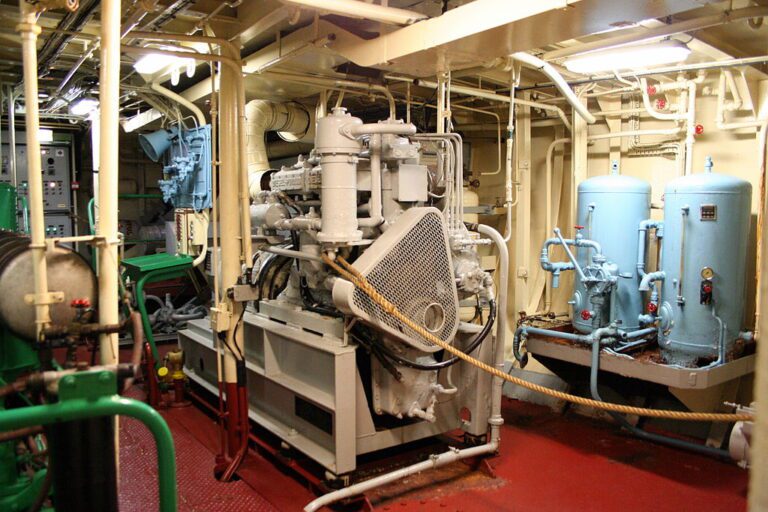

There are four systems needed to start and operate the engine:

- Fuel: The fuel system delivers the fuel from the storage tanks to the engine cylinders, where it is injected and burned to produce power. The fuel system consists of pumps, filters, valves, pipes, and injectors. The fuel must be of the right quality and quantity to ensure optimal combustion and prevent damage to the engine.

- Lubrication: The lubrication system circulates oil throughout the engine to reduce friction and wear between the moving parts. The lubrication system consists of pumps, coolers, filters, valves, pipes, and bearings. The oil must be clean and at the right temperature and pressure to provide adequate lubrication and cooling.

- Cooling water: The cooling water system removes heat from the engine and prevents it from overheating. The cooling water system consists of pumps, heat exchangers, valves, pipes, and radiators. The cooling water must be fresh or treated to prevent corrosion and scaling in the engine.

- Starting air. The starting air system provides compressed air to the engine cylinders to initiate the combustion process. The starting air must be dry and at the right pressure to ensure reliable starting and prevent damage to the engine.

Even when the ship is in port, these four systems are kept running to ensure that the engine can be started quickly if needed. This is because stopping and starting the engine frequently can cause thermal stress and mechanical fatigue in the engine components. By keeping the systems running, the engine is kept in a ready state and can respond to any emergency or operational demand.

PREPARATION

Before starting the engine, the Master or the OOW will give notice to the engineers usually one hour prior to the ship’s departure to give them enough time to make the engine ready.

These are the preparations need to do by engineers:

- Additional generator. This is need to run to ensure that the system has enough electrical power to handle additional loads. This helps reduce the load on the main engine and prevent blackouts or voltage fluctuations that could damage the electrical equipment or cause accidents.

- Engine Parts Lubrication. In this case, the turning gear will be use. This is necessary to ensure that the lubricating oil is evenly distributed on the bearing surfaces and that the temperature of the engine parts is uniform.

- Start the compressed air system. The majority of ship engines are initiated through the utilization of compressed air, which is contained within sizable air cylinders. The compressed air is stored in air bottles at high pressure and is released through a series of valves and pipes to the cylinders of the engine. The air pushes the pistons and rotates the crankshaft, which in turn moves the flywheel. When the flywheel reaches a speed of about 200 rpm, the fuel injection system is activated and the engine starts to run on its own power. The compressed air system is then shut off and the air bottles are recharged by an air compressor.

Upon meeting all the initial conditions, the ship’s main engine will be prepared for start.

STARTING THE ENGINE

Before giving the full control of main engine to bridge, trial starting should be done. The bridge and the engine room need to communicate and coordinate their actions. The engineers will inform the bridge officers that engine is ready for the test.

- Air blowing. The main engine is put on standby condition and air blowing is to be carried out to release any moisture or other residues inside the cylinders. There will be no combustion since fuel injection is not taking place at this time. The air blowing also helps to warm up the engine and reduce thermal stress.

- Bridge Control. Once the air blowing is performed successfully and all engine controls are working and in good condition. Engineers will give the control to bridge.

The bridge officers have now the control to start and stop the engine as needed during maneuvering and gradually increase the speed as required. As the ship starting to increase the speed, there is so-called “critical RPM” which is usually between slow and half ahead, depending on the type and size of the engine, the propeller design, and the load conditions. This can cause vibration and noise but will eventually stop once the main engine passed that critical RPM range.

When the ship is in full ahead, the engine speed can be slowly increased as required or as per instructions. After reaching the desired speed and entering the open sea, Master will inform the engineers the time for the “commencement of sea passage” which also means that maneuvering is also completed.

Starting the ship’s main engine requires careful preparation and execution. The steps outlined in this article are based on the general principles and best practices of marine engineering, but they may vary depending on the specific type and model of the engine. Therefore, it is necessary to consult the manufacturer’s manual and follow the instructions and safety precautions provided.

Related Article: How do Seawater and Freshwater Cooling Systems on Ships Work?