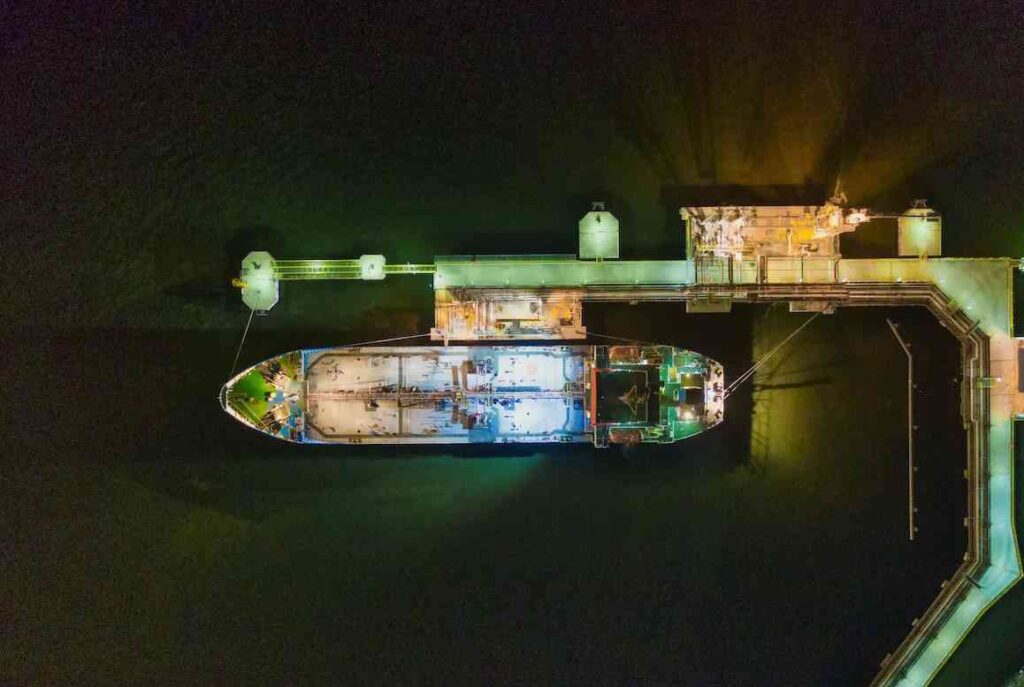

Mooring operations are one of the most important and hazardous tasks onboard ships. They involve securing the ship to a fixed or floating structure using ropes, wires or chains. Mooring operations require careful planning, coordination and execution to ensure the safety of the crew, the ship and the environment.

Let us explore the various aspects of mooring operations onboard ships, including the different types of mooring lines used, the procedures for securing a vessel to a fixed structure, and the safety considerations that must be taken into account during mooring operations.

EQUIPMENT USED IN MOORING OPERATION

- Mooring Lines: Mooring lines are ropes used to secure the vessel to a fixed structure. These ropes are typically made of synthetic materials such as nylon or polypropylene and can withstand high tensile forces.

- Bollards: Bollards are metal or concrete posts that are fixed to the quay or jetty. They are used to tie the mooring lines and hold the vessel in place.

- Fenders: Fenders are rubber or plastic pads placed between the vessel and the quay to prevent damage during the mooring operation.

- Mooring Winch: mechanical device used to control the tension of the mooring lines.

- Capstan: A capstan is a rotating device used to control the tension of the mooring lines. It is usually powered by an electric or hydraulic motor.

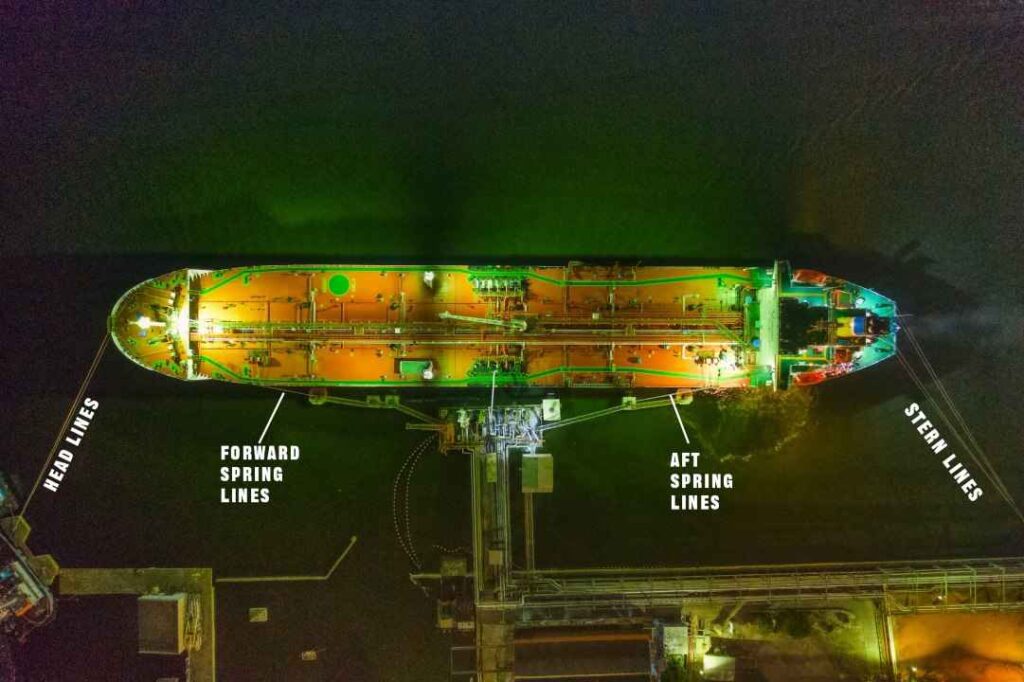

MOORING LINE SETS

When a vessel is alongside a berth, there are typically several sets of mooring lines used to secure the vessel to the quay or jetty. The exact number and arrangement of mooring lines will depend on several factors, including the size and type of the vessel, the conditions of the mooring operation, and the preferences of the ship’s crew. However, some of the most commonly used sets of mooring lines are:

- Breast Lines: Breast lines are mooring lines that run at right angles to the ship’s side and prevent it from moving away from or towards the berth. They are used to keep the ship in a fixed position along the quay and to facilitate loading and unloading operations. Breast lines are usually shorter than other mooring lines and are attached to bollards on the shore or to dolphins near the berth.

- Spring Lines: Spring lines are mooring lines that run diagonally from the vessel’s bow or stern to the quay or jetty. They are used to prevent the vessel from moving forward or backward along the dock, and to help control the vessel’s position during loading or unloading operations. Spring lines can also reduce the stress on other mooring lines by absorbing some of the forces caused by wind, waves or currents.

- Stern Lines: Stern lines are mooring lines that run from the vessel’s stern to the quay or jetty. It helps to keep the vessel in position and prevent it from swinging away from berth.

- Head Lines: Head lines are mooring lines that run from the vessel’s bow to the quay or jetty. Head lines help to keep the vessel in position and prevent it from drifting sideways or turning around.

The number and arrangement of these sets of mooring lines will depend on several factors, including the size and type of the vessel, the conditions of the mooring operation, and the preferences of the ship’s crew. The crew must be familiar with the correct arrangement and tension of the mooring lines to ensure that the vessel is secured safely alongside the berth.

MOORING PROCEDURES

- Preparing the Mooring Equipments. Determine the location of the mooring point and the type of mooring equipment required. This may include bollards, cleats, or other types of mooring hardware. The crew will typically start by preparing the mooring lines, which are the ropes or cables used to secure the vessel to the mooring point. These lines are typically made of strong, durable materials such as nylon, polyester, or steel wire. The crew will carefully inspect each line to ensure it is in good condition and free from any damage or wear that could compromise its strength. The lines must be untangled and laid out in the correct order, and if it is ship-to-ship transfer, the fenders must be attached to the vessel.

- Approach: Once the mooring lines are prepared, the crew will begin positioning the vessel alongside the mooring point. This requires careful navigation and communication between the crew members on board the vessel and those on shore. The crew will typically use a combination of engines and thrusters to position the vessel in the correct location.

- Attaching the Mooring Lines: Once the vessel is in position, the crew will begin attaching the mooring lines to the mooring point. This typically involves throwing the lines from the vessel to shore, where shore crew will secure them to the mooring hardware. Most of the time spring lines will be send first to help the vessel stayed in position but its still depends on the location and requirements of the terminal.

- Securing the Vessel: After the mooring lines are attached, the crew will use the mooring winch to adjust the tension of each lines to maintained the vessel in position.

- Checking the Mooring: Once the vessel is secured, the crew must check the mooring lines and fenders to ensure that they are holding up to the strain. They must also check the bollards and the quay to ensure that there is no damage or signs of wear. Throughout the mooring operation, the crew will need to remain vigilant and ready to make adjustments as needed. This may include repositioning the vessel, adjusting the tension on the mooring lines, or responding to changes in weather or other environmental conditions.

- Departure: When the vessel is ready to depart, the mooring lines must be untied in the correct order. The pilot and the crew must ensure that the vessel is clear of the quay or jetty and that there are no hazards in the way.

The crew must be familiar and well-trained with the equipment used and the procedures for a safe operation. Many accidents had happened in the past due to improper mooring practices, resulting in injuries, fatalities and environmental damage. Properly executed mooring operation can help prevent damage to the vessel and ensure the safety of the crew and other personnel involved in the operation.