Bunkering is the process of refueling a ship with the necessary fuels for its voyage. This operation can be done from a barge or a terminal to a ship’s tanks. This is regularly done to ensure that the vessel has enough fuel to complete its journey safely and efficiently. However, bunkering also comes with a range of challenges, such as safety risks, environmental concerns, and regulatory compliance.

TYPES OF FUELS

- Marine Gas Oil (MGO): This is a type of diesel fuel that meets the International Maritime Organization’s (IMO) low sulfur content requirement of 0.1%. MGO is used by ships in emission control areas (ECAs), such as the Baltic Sea and the North Sea, where stricter environmental regulations apply.

- Marine Diesel Oil (MDO): This is a blend of heavy gas oil and marine gas oil. MDO has a higher sulfur content than MGO, ranging from 0.5% to 1.5%. MDO is used by ships outside of ECAs that have engines that can handle the lower quality fuel.

- Intermediate Fuel Oil (IFO): This is a residual fuel that is derived from crude oil after the lighter fractions have been removed. IFO has a high viscosity and density and requires heating before use. IFO has a sulfur content of up to 3.5%. IFO is used by ships that have boilers or steam turbines for propulsion or power generation.

- Heavy Fuel Oil (HFO): A type of IFO with the highest viscosity and density. HFO is the cheapest and most widely used marine fuel, but also the most polluting and harmful to human health and the environment. HFO is used by large cargo ships and cruise liners that have special equipment to handle the fuel.

- Low Sulfur Fuel Oil (LSFO): A type of IFO with a reduced sulfur content of 0.5% or less. LSFO was introduced in 2020 as part of the IMO’s global sulfur cap regulation that aims to reduce air pollution from shipping. LSFO is used by ships that do not have exhaust gas cleaning systems (scrubbers) or alternative fuels.

- Liquefied Natural Gas (LNG): A natural gas that has been cooled to -162°C and converted into liquid form for easier storage and transport. LNG has a very low sulfur content and emits less carbon dioxide and nitrogen oxides than other marine fuels. LNG is used by ships that have dual-fuel engines or dedicated gas engines that can burn LNG directly.

The choice of bunker fuel depends on various factors such as engine type, environmental regulations, availability, price, etc. The bunker fuel should meet the specifications given by ISO standards such as ISO 8217:2017, which defines the requirements for fuels for use in marine diesel engines and boilers.

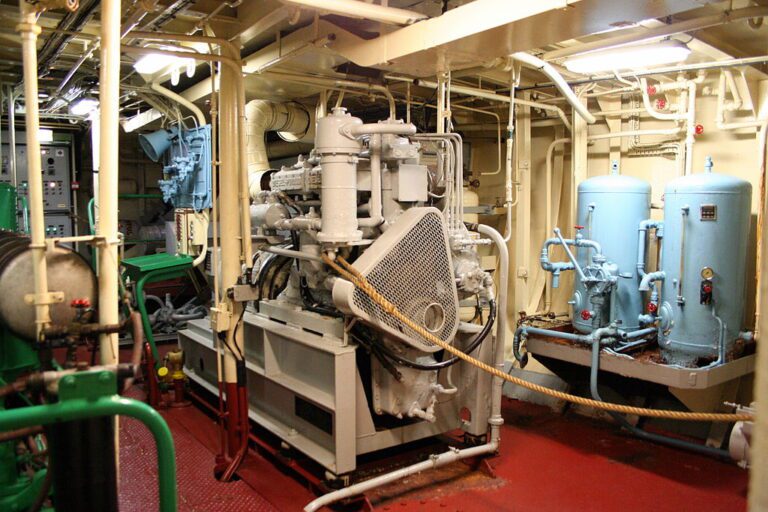

STORAGE TANKS

The fuels used for bunkering on ships are stored in dedicated storage tanks onboard the vessel. These tanks must be properly maintained to ensure their safety and integrity. These tanks are separate from the cargo tanks and the ballast tanks, and they have specific requirements for safety and environmental protection. Designated tanks must be properly maintained and inspected to avoid leaks, spills, or explosions. They are equipped with adequate ventilation, gauges, valves, and pumps to control the flow of fuel during bunkering operations.

BUNKERING PROCEDURES

Bunkering procedures can vary depending on the type of fuel being used and the specific vessel being fueled. However, there are some general best practices that should be followed.

Here are some of the important safety procedures that should be followed during bunkering:

- Ordering: The chief engineer should calculate the volume and grade of fuel oil or lube oil needed for the ship, and order it from a reliable supplier. The order should specify the delivery date, time, place and mode of bunkering, as well as any special requirements such as heating or filtering.

- Preparation: The ship should prepare for bunkering by ensuring that all equipment, tanks and pipelines are ready and in good condition. The ship should also communicate with the bunker supplier or barge to confirm the details of bunkering and exchange relevant information such as contact numbers, signals and emergency procedures.

- Pre-bunkering: Before starting the bunkering operation, the ship and the bunker supplier or barge should conduct a pre-bunkering meeting to discuss and agree on the bunkering plan, including the sequence of tanks to be filled, transfer rate, sampling method and stop signals. The ship and the bunker supplier or barge should also complete a pre-bunkering checklist to verify that all safety measures are in place.

- Bunkering: During bunkering operation, both parties should monitor the transfer process closely and follow all safety precautions. The ship should check the quantity and quality of fuel oil or lube oil received by using flow meters, gauges, sounding tapes and samples. The ship should also maintain proper communication with the bunker supplier or barge throughout bunkering operation.

- Post-bunkering: After completing bunkering operation, both parties should stop pumping safely and disconnect hoses carefully. The ship should record the final quantity and quality of fuel oil or lube oil received by using ullage reports, bunker delivery notes (BDN) and certificates of quality (COQ). The ship should also inspect all equipment, tanks and pipelines for any leaks or damages.

REGULATIONS

Bunkering operation is subject to various international regulations that aim to ensure safety, security and environmental protection. Some of the main regulations are:

- The International Convention for the Prevention of Pollution from Ships (MARPOL), which sets limits on the sulphur content and emissions of bunker fuels, and requires ships to keep records of their fuel consumption and transfers.

- The International Convention for the Safety of Life at Sea (SOLAS), which establishes standards for fire prevention and firefighting equipment, emergency procedures and communication systems during bunkering operation.

- The International Ship and Port Facility Security (ISPS) Code, which requires ships and port facilities to implement security measures to prevent unlawful acts that may endanger bunkering operation.

- The International Maritime Organization (IMO) Guidelines on Bunkering Operation, which provide best practices and recommendations for safe and efficient bunkering operation.

Ships and bunker suppliers must comply with these regulations and any other applicable national or local laws when conducting bunkering operation. Failure to do so may result in fines, penalties or legal actions.