Image credit: Lokal_Profil and KVDP, CC BY-SA 2.5 <https://creativecommons.org/licenses/by-sa/2.5>, via Wikimedia Commons – For presentation purposes only.

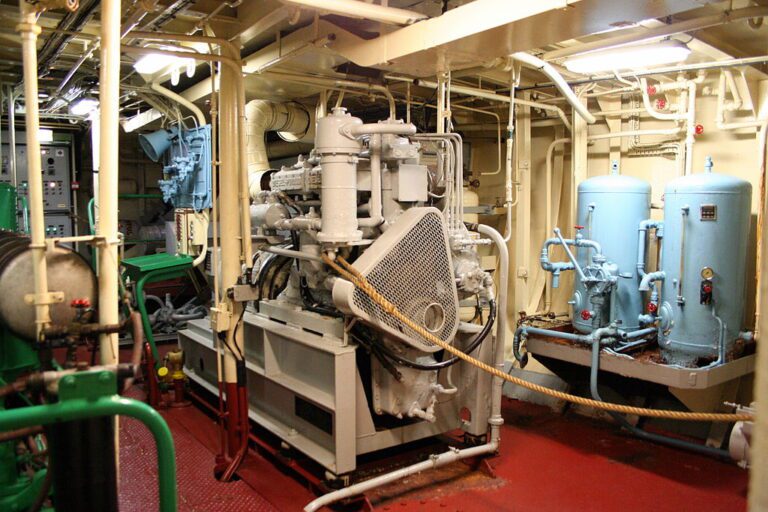

A ship’s engine needs to burn fuel to generate energy. This combustion process can produce excess heat that can damage the metallic components or can even fail entirely if not monitored. Therefore, to prevent this damage, a cooling system is necessary to regulate the temperature of the engine.

TYPES OF COOLING SYSTEM ONBOARD SHIPS

SEAWATER COOLING SYSTEM

BASIC COMPONENT OF SEAWATER COOLING SYSTEM

The basic components of a ship’s seawater cooling system include:

- Seawater Pump: The seawater pump is responsible for drawing seawater from the sea and supplying it to the heat exchangers. The pump’s capacity is determined by the ship’s size, the amount of heat to be dissipated, and the required flow rate.

- Heat Exchangers: The heat exchanger transfers heat from the ship’s engine to the seawater flowing through the tubes.

- Overboard Valves: The overboard valves control the flow of seawater out of the system and into the sea. These valves are located at the discharge end of the seawater piping system and are responsible for regulating the system’s pressure and preventing seawater from backing up into the heat exchangers.

TYPES OF HEAT EXCHANGERS

- Tube type: It consist of a tube bundle inside a larger shell, where one fluid flows through the tubes and another fluid flows over the tubes inside the shell. This type of heat exchanger can handle high pressure and temperature applications, and can be built in single or double pass configuration.

- Plate type: Plate type heat exchangers are designed with sets of multiple parallel plates that form passageways for the fluids to flow between them. This type of heat exchanger has a small footprint and is suitable for low pressure and temperature applications. Gaskets are used to prevent the mixing of the fluids in plate type heat exchangers.

DIFFERENT STYLES OF SEAWATER COOLING SYSTEMS

- Direct cooling. In a direct cooled system, seawater is directly used as a cooling medium for the machinery. The seawater is drawn from the sea chest, pumped through the machinery heat exchangers, and then discharged overboard. This system is simple and efficient, but it exposes the machinery to corrosion and fouling from seawater, make it requires more frequent maintenance and cleaning.

- Centralized cooling. In a centralized cooling system, seawater is used to cool a closed circuit of freshwater that circulates through the machinery. The seawater is drawn from the sea chest, pumped through a central freshwater cooler, and then discharged overboard. The freshwater is pumped through the machinery heat exchangers, and then returned to the central cooler. This system reduces the corrosion and fouling of the machinery, but it requires more components and maintenance.

Depending on the type and size of the ship, one or both of these systems may be used for different purposes.

FRESHWATER COOLING SYSTEM

Though ships can use seawater for cooling, it can cause corrosion to the part of the ship. Therefore, most ships have a freshwater cooling system. A freshwater cooling system on ships is a type of central cooling system that uses freshwater as a cooling medium for the engine room machinery. The freshwater is circulated in a closed circuit through heat exchangers, where it absorbs the heat from the machinery and transfers it to seawater.

The freshwater cooling system on ships consists of three different circuits:

- High-Temperature Circuit: The high-temperature circuit is used for cooling the machinery that operates at high temperatures, such as the main engine jacket water system, the freshwater generator, and the diesel generator during standby condition. The high-temperature freshwater is maintained by low-temperature freshwater and is circulated by electrical cooling water pumps. The high-temperature circuit is connected to the seawater central cooler through a temperature control valve, which regulates the flow of seawater according to the temperature of the freshwater.

- Low-Temperature Circuit: The low-temperature circuit is used for cooling the machinery that operates at low temperatures, such as the auxiliary systems. The low-temperature circuit is directly connected to the main seawater central cooler, hence its temperature is lower than that of the high-temperature circuit. The low-temperature circuit also comprises an expansion tank, which is common to both circuits and compensates for the loss and thermal expansion of freshwater in the system The hydrophore system or distilled water tank can be utilized, along with a freshwater refilling pump, to fill the expansion tank.

- Seawater Circuit: In order to bring down the temperature of the closed circuit freshwater, the seawater central cooler employs the use of seawater circuit as a cooling agent. The seawater is drawn from the sea chest by an ejector pump and passes through a strainer to remove any debris or impurities. The seawater then enters the seawater central cooler, where it cools down the freshwater by exchanging heat. The seawater then exits the cooler and is discharged overboard through an overboard valve.

Seawater and freshwater cooling systems are necessary for maintaining the normal working temperature and performance of the ship’s engine and other machinery. Both systems have advantages and disadvantages, depending on the type and size of the ship, the environmental conditions, and the maintenance requirements. Therefore, it is important to understand how these systems work and how to operate them safely and effectively.