Global trade and transportation rely on ships to carry billions of tons of cargo and millions of passengers each year. The ships’ power and propulsion systems depend on a complex network of technologies, among which the auxiliary engine plays an important role. Although the main engines receive most of the attention, the unsung heroes of the ship’s power and propulsion systems are the auxiliary engines. In this article, we will delve into the world of ship’s auxiliary engines – what they are, why they are essential, and how to maintain peak performance.

What Are Ship's Auxiliary Engines?

Definition and basic functions

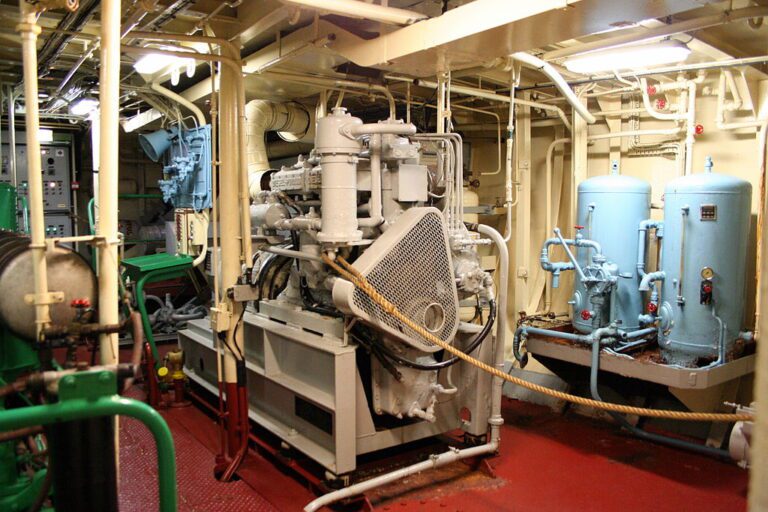

Auxiliary power units (APUs), or ship’s auxiliary engines, are small engines installed on ships to provide electrical power for various functions on board. They do not power the ship’s main propulsion system but instead provide the necessary energy to run other systems, including air conditioning, refrigeration, communication equipment, and lights. Ship’s auxiliary engines have three primary functions:

- Generating electrical power – Auxiliary engines generate electricity to power the ship’s systems and equipment by converting fuel, such as diesel or gas, into mechanical energy, which is then transformed into electrical energy using a generator.

- Driving pumps – Auxiliary engines also drive various pumps on the ship, including those used for fuel transfer, water supply, and fire suppression.

- Providing emergency backup power – In case of a power outage, auxiliary engines can serve as a backup power source to keep essential systems running until the main engines can be restarted or repaired.

Types of Auxiliary Engines

Ships utilize various types of auxiliary engines, each possessing specific functions and capabilities. Below are some of the examples.

- Diesel engines. Diesel engines are highly efficient and reliable, often utilized for generating electrical power and driving equipment such as pumps.

- Gas turbines. Gas turbines are commonly found on larger ships that require high-speed propulsion or as emergency backup power sources due to their fast response time and high power output.

- Steam Turbines. Although they are not as common as they used to be, some older ships still rely on steam turbines, which generate electricity or drive other equipment using steam generated from a boiler.

Differences Between Main Engines and Auxiliary Engines

Main engines propel the ship while auxiliary engines serve a different purpose. Some differences between the two include:

- Main engines are larger and more powerful than auxiliary engines, which are smaller and less powerful since they only produce enough power for the ship’s systems and equipment.

- Main engines consume more fuel than auxiliary engines because of their greater power output.

- Ships typically have multiple auxiliary engines for backup in case of engine failure, while they may have only one or two main engines because they are more reliable and less likely to fail.

Why Are Auxiliary Engines Necessary for Ships?

Power generation and distribution

Auxiliary engines are necessary for ships because they provide electrical power for the various systems and equipment on board. While the main engines are responsible for propelling the ship forward, they do not generate enough electricity to power all of the ship’s systems. Auxiliary engines provide the additional power needed to keep the ship running smoothly. Some specific systems that rely on auxiliary power include:

- Lights and electrical outlets – Essential for providing lighting throughout the ship, as well as powering various electrical devices, such as computers, phones, and other equipment.

- Air conditioning and refrigeration – Critical for maintaining a comfortable living and working environment on board the ship, as well as keeping food and other perishable items fresh.

- Communication equipment – Ships rely on a variety of communication equipment, such as radios, satellite phones, and radar systems, to stay in contact with other vessels and port authorities.

Essential Backup Systems

Auxiliary engines provide backup power in case of an emergency, ensuring that ships do not become stranded and vulnerable to hazards such as storms, currents, and other vessels, if the main engines fail. Critical systems that rely on auxiliary power include:

- Navigation systems – Auxiliary power enables these systems to guide the ship safely through the water. Navigation equipment such as GPS, radar, and depth sounders can be powered by auxiliary engines.

- Communication systems – Communication is very important during emergencies for calling for help or coordinating with other vessels. Auxiliary engines can power communication equipment such as radios, satellite phones, and distress beacons.

- Emergency lighting – In case the ship loses power, auxiliary engines can power emergency lighting which is essential for guiding crew members to safety.

Fuel Efficiency and Emissions Reduction

Auxiliary engines enable ships to operate more efficiently and reduce their emissions by powering non-propulsion systems with smaller engines. This reduces fuel consumption and emissions since main engines are most efficient at high loads. Furthermore, some auxiliary engines emit fewer pollutants and are more fuel-efficient than older engines. Using auxiliary engines for fuel efficiency and emissions reduction provides the following benefits:

- Reducing fuel consumption – Ships can reduce their overall fuel consumption, save money, and reduce their environmental impact by using smaller, more fuel-efficient engines for non-propulsion systems.

- Reducing emissions – Ships can meet emissions regulations and reduce their environmental impact by using auxiliary engines designed to emit fewer pollutants and be more fuel-efficient.

- Optimizing load – Using smaller engines for non-propulsion systems enables ships to optimize the load on their main engines, improving their overall efficiency and reducing engine wear and tear.

Maintenance and Operation of Auxiliary Engines

Regular maintenance

Regular maintenance is necessary for auxiliary engines to operate smoothly, just like other machinery. This maintenance comprises of:

- Changing the engine oil regularly to lubricate the engine and prevent wear and tear on its components.

- Regularly changing filters such as air and fuel filters is crucial to prevent contaminants from entering the engine and causing damage.

- Routine cleaning and inspection to detect wear and tear should be performed regularly. Debris or buildup that could interfere with the engine’s operation should be removed.

Proper Operation

Proper operation of auxiliary engines is also important to ensure their longevity and reliability, in addition to regular maintenance. To achieve this, consider the following key factors when operating auxiliary engines:

- Ensure optimal performance and fuel efficiency by operating auxiliary engines at the appropriate load. Overloading or underloading the engine can cause damage and reduce its lifespan.

- Prevent damage and ensure proper operation by starting and stopping auxiliary engines according to the manufacturer’s recommendations.

- Follow proper shutdown procedures to prevent damage to the engine and ensure safe operation. This may involve tasks such as cooling the engine down before shutting it off.

Training and Certification

To ensure the proper operation and maintenance of auxiliary engines, it’s important to train and certify crew members responsible for them. Consider the following training and certification requirements:

- Manufacturer training – The manufacturer of the auxiliary engine should provide training to crew members to ensure their familiarity with the engine’s operation and maintenance.

- Certification requirements – Depending on the ship’s size and type, crew members may need certain certifications to operate and maintain auxiliary engines.

- Continuing education – Crew members should stay up-to-date with the latest developments in auxiliary engine technology and maintenance practices as technology and regulations change. Ongoing training and education can prepare crew members to operate and maintain these critical systems.

Modern ships rely heavily on auxiliary engines as they provide power for various onboard systems and operations. Operating and maintaining auxiliary engines correctly is important to ensure their reliability and longevity. Crew members can learn how to operate and maintain auxiliary engines by undergoing proper training and certification. Ship owners and operators can help guarantee that their auxiliary engines continue to provide reliable and efficient power for years to come by following manufacturer recommendations, adhering to certification requirements, and staying up-to-date on the latest technologies and practices.